If you work in the packaging industry, or an industry that deals with a lot of packaging material (think e-commerce, retail, shipping, etc.), it’s probably crossed your mind a few times—what’s the difference between hot melt tape and acrylic tape, and when should you use one instead of the other? If that question hasn’t popped into your mind, this less specific one probably has: what kind of tape should I be using? At Sigma Supply, we get asked this question a lot by our clients (and our coworkers new to the packaging industry!) so we hope that this article will work as a guide for you to make the best decision for your packaging needs.

Hot melt and acrylic tape may look the same sometimes, but their applications are very different. If you find yourself working with tape applications often, but are still unsure of the differences, this can make it difficult to decide on which tape is best for your needs, so let’s dive into the details below on main differences, pros and cons, and when to use each one!

What is Hot Melt Tape?

Hot melt tape is a versatile, superior-hold adhesive tape made out of a polymer, resin and wax combination. It is fast to tack, easy to apply and adheres to most packaging materials (whether it be a brand-new cardboard box, a recycled container, or bubble wrap mailer). Hot melt tape is strong, but it doesn’t fare well in unstable or extreme climate conditions, and it will deteriorate and discolor over time (especially when exposed to UV light), so using it for long-term storage is not ideal. Let’s take a look at some of the pros and cons:

|

PROS |

CONS |

|

High shear (holding power) |

Not suitable for use in extreme or unstable climates/temperatures |

|

Can be used by hand, with a hand-held machine, or industrial carton sealing equipment |

Discolors over time |

|

Quick adhesive |

Deteriorates over time when exposed to UV light |

|

Consistent + easy application |

Not ideal for long-term storage (short shelf life) |

When to Use Hot Melt Tape

Now that we know some of the typical characteristics of hot melt tape, let’s go over some examples of when to use it! Hot melt tape is best when you:

- Need a strong tape that can hold heavy objects for a short period of time

- Are shipping or transporting heavy packages

- Need a tape suitable for industrial purposes, such as heavy-duty carton-sealing machines

- Need something consistent and easy to apply

What is Acrylic Tape?

Acrylic tape is made from, well, you guessed it: acrylic! Created by crosslinking monomers, it comes as either water or solvent based, and is extremely resistant to degradation. It has a low shear (remember: shear = strength) but its biggest play in the game of tapes is that it can be used in extreme temperatures (think freezer storage, or warehouses without temperature control), can withstand no-to-high humidity, is UV resistant, and has exceptional shelf life in comparison to hot melt tape. Acrylic tape may not seem as durable as hot melt tape on the forefront, but depending on your application needs, it has some serious benefits.

|

PROS

|

CONS

|

|

Withstands an extreme temperature range (-30 to 200 degrees Fahrenheit) |

Can be challenging to apply |

|

Can handle zero to high humidity |

Slow to tack |

|

Is UV light resistant |

Low sheer (holding power) |

|

Does not discolor over time |

Not recommended for industrial carton sealing machines |

|

Longer shelf life |

|

|

Can be repositioned before adhesion takes place |

|

When to use Acrylic Tape

Acrylic tape is best when you need a tape that will:

- Last in long-term storage

- Stay put through extreme high or low temperatures or humidity levels

- Not deteriorate when exposed to UV light

- Hold your lightweight cartons

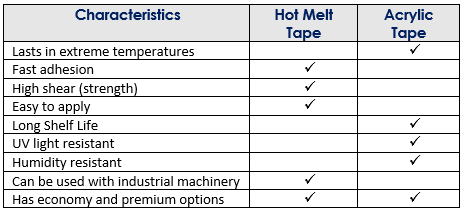

Hot Melt Vs. Acrylic Tape: Key Takeaways

Hot melt tape is high shear (strong) and usually the best option for heavy packaging, but does deteriorate over time and is not recommended for long-term storage. Acrylic tape is low shear (not very strong) so may not be suitable for most industrial applications, but it is resistant to extreme temperatures (high and low) and has a long shelf life, which makes it an ideal candidate for long-term storage. Need more help deciding what kind of tape you need? Call us today to speak with one of our tape specialists!

Comparison

Common Packaging Tape Issues

If you’ve been experiencing some issues with your tape, you’re not alone. It can be hard to determine what the cause is, but there is always a solution! Have any of the below problems?

- Tape won’t stick to packaging upon application

- Tape stretches or breaks during application or transit

- Tape peels off after a certain amount of time

- Inconsistent dispensing from machine or hand-held tape applicator

- Packages pop open

- Customers complain that your packaging is hard to open

- Excessive tape waste

- Sustainability concerns

If you answered “yes” to any of the above…

Let Sigma Help You!

Picking the right one doesn’t have to be stressful—that’s what you have us for! Take the guessing out of the equation and let our tape specialists do the heavy lifting for you (metaphorically speaking, of course—we don’t actually want to lift anything heavy if we can help it). If you’re having problems with your current tape supply, or you’re still not sure what tape is best for the job, give us a call!

Click here to see our available Hot Melt and Acrylic tapes! Need to buy in bulk? Contact us to speak with a representative about our bulk discounts!